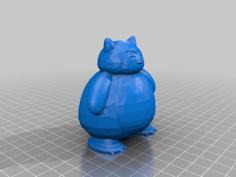

I would like to introduce to you the 5th version of my wind-up boat.

After the 4th version i got a lot of feedack on Facebook, which I have implemented as well as possible.

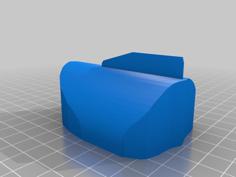

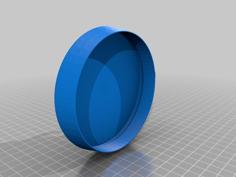

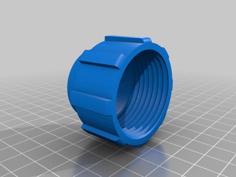

As you can see there is a much larger wind-up weel. The boat can now be wind up easily even with wet hands. The button has also become a little bit thicker to offers more grip.

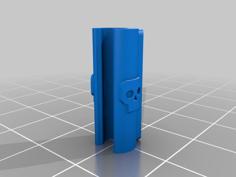

The sharp edges on all components were rounded. I also set the screws in a way that the heads are up. No more sharp threads on the top.

Next, I've added a rigid rudder, which means the boat is no longer drifting to the right side any more. That works quite well. - better than expected.

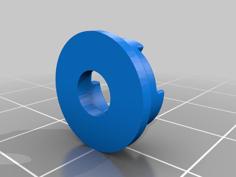

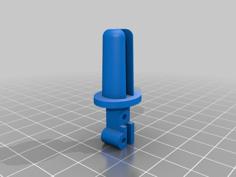

The biggest changes were in the transmission. All the gears were redesigned. For the direction change in the back i used a spiral bevel gear, which produces ridiculously little friction. It is designed in a way, that the axial force goes to the rear and the friction occurring is almost neutralized by the back pressure of the propeller. This works absolutely fantastic in the water! The gears now have all got an counter bearing. So tilting and the associated friction is prevented now. So the whole transmission is way more efficient, runs faster and longer in a straight direction, without going crazy when pulling up. A win-win-win construction. :)

In version 5 you only need 4 different screw sizes.

2x M3x10 (optional for attaching the gearbox to the main body)

4x M3x20

5x M3x30

1x M3x40

you also need

4x M3 Nyloc nuts

6x M3 normal nuts or alternatively Nylocs

To test, if your print settings are correct, I have constructed a small functional benchmark. You have to print the most important gears – the bevel gears - and a small holder with a pin. Assable it and test it for function. Adjust your first layer and extrusion multiplier so that the two gears mesh easily and then print the rest of the model with the same settings. It is absolutely important that these two gears run well. So start with the benchmark. When it works well, you can use this gears for your boat.

And please print everything in PLA, otherwise the spiral is not stiff enough and the gears generate too much friction. I drilled the holes in my gears with a small 3H7 reamer. You can also use a spiral drill. Do it anyway, so nothing gets stuck.

I would like to thank Janssen86 for providing the gear library for OPEN SCAD on Thingiverse. I designed the whole boat with Fusion 360, but such a spiral bevel gearbox is a completely different thing. Much more difficult to design then i expected. That would not have been possible without Janssen's library. Thanks again.

Happy printing!

https://www.youtube.com/watch?v=3UjEpt3KLiE

Instructions: (german)

https://youtu.be/ygzd07_NlA8

edit: 06.04.2020

As requested, I uploaded a stiffer version of the "Mitnehmer" and the "Aufzieher". The square is now 1mm longer and should transmit a little more torque.

edit: 12.04.2020

I added the file "easySchraube" for easier printing. But it could be less efficient!