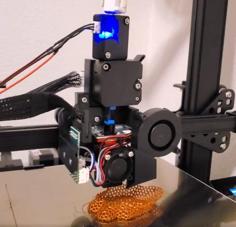

Here's everything you need to easily upgrade the Ender 6 to use X and Y linear rails. I've kept it as simple as possible and easy to install to minimize issues. These mounts work with my BIQU H2 mounting kit at https://www.thingiverse.com/thing:4893522.

If you want to also update your z-axis to linear rails, I have a mount at https://www.thingiverse.com/thing:6196091.

This kit eliminates the y-axis v-wheel plates which saves weight. You can also increase the y-axis travel by 15mm (up to 25mm max) with my Y endstop relocation mount. If you try increasing the distance past 25mm, you risk having the x-carriage mount hit the z-axis leadscrew when the bed is near the top.

If you want to use a plexiglass lid, there's one at https://www.thingiverse.com/thing:4787779 but it will need s spacer which can be found at https://www.thingiverse.com/thing:5273044. Standard lids will not work as the linear rail blocks extend slightly over the edge of the 2040 extrusion.

These were inspired by Tertullidan's x-carriage model (https://www.thingiverse.com/thing:4800961) and Bennett101's y-axis mount (https://www.thingiverse.com/thing:4982000).

More Ender 6 models at https://www.thingiverse.com/vampyrex13/collections/my-ender-6-models.

Updates

• 2022.02.28: Stronger x-axis mount v2 released in both the normal and reinforced variations.

• 2022.02.23: Y-axis assembly stablizer added and y-axis mounting holes adjusted for better fitment.

• 2022.02.22: Strengthened the mounting holes for the y-axis mount.

Klipper Firmware Notes

Make the following changes. If you are currently using my BIQU H2 mount, this keeps the ~7mm border on the front edge of the bed and ~1mm clearance between The Claw fang duct and belt.

• +0mm Endstop: No changes required.

• +15mm Endstop:

[stepper_y]

position_endstop: Add 15 to the current Y value.

position_max: Add 15 to the current Y value.

[safe_z_home]

home_xy_position: Add 7.5 to the current Y value.

[bed_mesh]

mesh_max: Add 15 to the current Y value.

• +25mm Endstop:

[stepper_y]

position_endstop: Add 25 to the current Y value.

position_max: Add 25 to the current Y value.

[safe_z_home]

home_xy_position: Add 12.5 to the current Y value.

[bed_mesh]

mesh_max: Add 25 to the current Y value.

Slicer Notes

• Bed Size: Add 15 or 25 to the current Y value depending on which endstop you used.

Versions

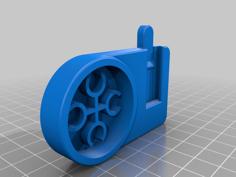

• There are two x-axis mounts; the normal version (lighter) and the reinforced one. The normal one should be fine for most users, but if you're running your printer hard and fast, you may want to use the reinforced one instead.

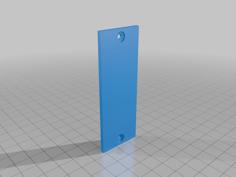

• There are three endstop mounts; +0mm, +15mm to the y-axis, and +25mm to the y-axis. +15 is the safest while +25 is the maximum. If you use the +25 endstop, the Z leadscrew might hit the back of the x-carriage bracket when the bed is lower because of how the leadscrew wobbles.

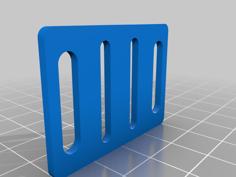

• There are two linear rail alignment blocks; the regular one and an extended one that is 3mm longer on one side. The extended side allows you to use it without having to remove the acrylic side covers.

Hardware

Linear Rails (every other hole):

• (24) M3x10mm socket cap screws

• (24) M3 t-nuts

X-Carriage Mount:

• (4) M5x20mm socket cap screws

• (4) M5 nuts

• (2) M5 washers (reuse existing)

X-Carriage Linear Rail Block:

• (4) M3x10mm socket cap screws

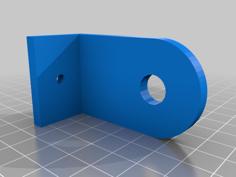

Y-Axis Mounts:

• (4) M4x30mm socket cap screws

Y-Axis Linear Rail Blocks:

• (8) M3x8mm socket cap screws

Y Assembly Stabilizers:

• (4) M4x10mm socket cap screws

• (4) M4 t-nuts

Y Endstop Mount

• Reuse existing screws

Printing Notes

• Print the mounts at 60% infill with 5 vertical and horizontal layers in PETG minimum. ASA or ABS is recommend.

• Use supports for the y-axis mounts. The x-axis should be fine without them.

Installation Notes

• You may want to consider re-routing your reverse Bowden tube into the case as this kit is not compatible with the filament guide. You can see how I have mine routed at https://www.thingiverse.com/thing:5227427.

• The Y endstop must be relocated with the new mount as you will be removing the y-axis v-wheel plate that normally triggers the endstop. I recommend doing this first so you don't forget.

• You will need 3 linear rails total. You need clean them so they move smoothly. There are videos and guides on how to do this online. Be careful not to lose any of the ball bearings.

• Print out two rail alignment blocks (one for each end) to make sure your rail is sitting straight.

• You don't need to use a bolt in every hole for the linear rails. I ended up doing every other hole.

• Be sure to lubricate the ball bearings. I used Super Lube synthetic oil with PTFE particles for mine. I applied two drops to the bearings on each side then ran the block back and forth on the rail several times to spead the lubricant.

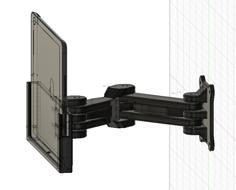

• The v-wheel plates must be removed to install the y-axis mounts. They are held in place with two M3 screws.

• I was able to install y-axis mounts without having to loosen the belts by installing the outer most screw on top, then pivoting the idler wheel assembly into place to install the other screw. You can use a small adjustable wrench as leverage to make sure everything is lined up and straight.

• If you end up needing to loosen the belts, you can watch the video at https://youtu.be/70l25LiKZvw for instructions. Take a picture or draw a diagram of the belt route in case it slips off completely.

• The v-wheel plates kept the idler wheel assembly secured at a 90° angle with the gantry 2020 extrusion, so you will need to install the y-axis assembly stabilizers to prevent any movement once you have everything lined up. You only need to install one on each end on the backside.

• The the x-axis linear rail and mount can be installed without having to take the belts off. I installed it to the linear rail block first, then unbolted my H2 extruder and cable management so that I could access the x-carriage v-wheel bolts.

• You'll need to use washers for the bottom two x-carriage mount bolts. You can reuse the original ones.

Parts

Below is my list of parts I used (affiliate links).

• 350mm MGN12H Linear Rails: https://www.amazon.com/dp/B082DGKK1D/ref=cm_sw_r_as_gl_apa_glt_fabc_T2RD7HYG3VREQKPA30SA?_encoding=UTF8&psc=1&linkCode=ml1&tag=vampyrex13-20

• Super Lube: https://www.amazon.com/dp/B000BXOGHY/ref=cm_sw_r_as_gl_apa_glt_fabc_T2RD7HYG3VREQKPA30SA?_encoding=UTF8&psc=1&linkCode=ml1&tag=vampyrex13-20

Buy Me a Coffee?

Do you like my work? You can buy me a coffee at https://ko-fi.com/vampyrex13.

![[19″] Rack Cable Guide XL 3D Printer Model](https://cdn.3axis.co/assets/ac/bd/3c/6e/acbd3c6e-2739-4e09-8d19-5012420354fa/images/02608790-ad8a-4dcf-8aa5-cc95d7346ff4_thumb.jpg)