The way to roll: Portable, foldable wheelchair ramp

Introduction

In our school project, we focused on creating an innovative solution to improve accessibility: a wheelchair ramp that is both easy to build and affordable. This project aligns with our commitment to inclusivity and practical engineering. We focused on several key features:

- Cheap

- Portable

- Printable

- Adjustable (obstacle heights)

Technical Details

- Width:

300 mm - 800 mm (adjustable) - Length:

1430 mm - Maximum Height

50 mm - 250 mm - Weight:

8100 g - Printing Time:

~175 h - Building Time:

~2 h - Print Material:

PLA/ASA - Maximum load capacity:

Tested 200 kg

Designed in Fusion 360 by AutoDesk (https://www.autodesk.com/products/fusion-360/personal)

Material List

| Size | Quantity | Type | Usage | price (CHF) |

|---|

| 4x45 | 12 pcs. | countersunk Screw | To screw printed part to wood | 2.95 |

| 4x35 | 12 pcs. | countersunk Screw | To screw printed part to wood | 2.90 |

| 4x35 | 4 pcs. | countersunk Screw | To attach the handle | 1.00 |

| 4x30 | 8 pcs. | countersunk Screw | For the folding system | 1.80 |

| M8x35 | 2 pcs. | countersunk Screw | For the folding system | 5.00 |

| M8 lock | 2 pcs. | nut | For the folding system | 1.20 |

| M6 | 32 pcs. | washers | For every screw except handle and M8 | 8.25 |

| 608 ZZ | 12 pcs. | ball bearing | For the folding system | 5.90 |

| 255mm M20 | 4 pcs. | PVC pipe | For the folding system | 7.30 for 2m |

| 140mm M20 | 1 pcs. | PVC pipe | For the handle | - |

| 200x150 | 8 pcs. | rubber mat | For the endings | 6.45 |

| 150x150 | 2 pcs. | rubber mat | To prevent slipping off on the edge | - |

| 180x150 | 2 pcs. | metal sheet | To add strength on the edge | 9.60 |

| 1000x150x21 | 2 pcs. | screen printing plate | For bottom component of main ramp | 40.0 |

| 200x150x21 | 2 pcs. | screen printing plate | For top component of main ramp | - |

| Tesa Tape | 1 pc. | double sided tape | To attach metal sheet to components | 11.50 |

| UHU Power | 1 pc. | All-purpose adhesive | To attach rubber mat to PVC tubes | 4.65 |

| 330g | 1 roll | PLA 3D Print material | For the small components | 7.10 |

| 1700g | 1 roll | ASA 3D Print material | For the big components | 44.00 |

| | | | Total |

| | | | 159.60 |

Print Settings

These settings are essential for the big component to be stable enough to support the weight needed.

Item Settings

- Layer Height:

0.20 mm - Initial Layer Height:

0.20 mm - Wall Line Count:

5 - Top/Bottom Pattern:

Line - Infill Density:

40 % - Infill Pattern:

Cubic

Parts to print

| Part | Quantity | Material |

|---|

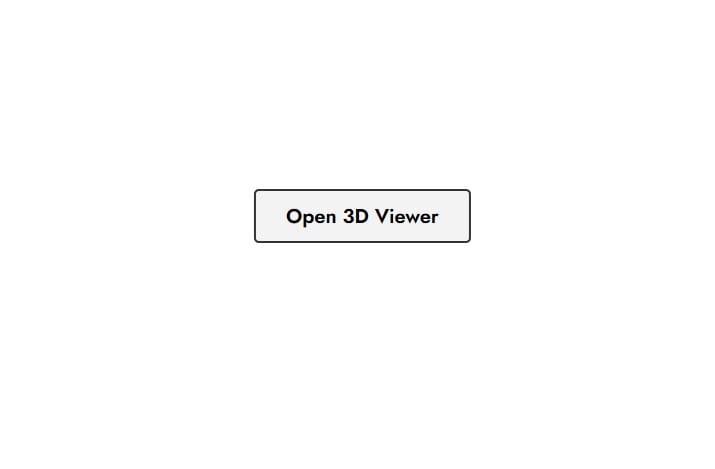

| Main connector | 2 | ASA |

| Handle Left | 1 | PLA |

| Handle Right | 1 | PLA |

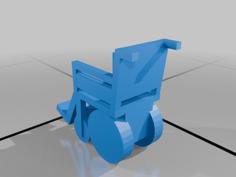

| Folding Limb 1 | 4 | PLA |

| Folding Limb 2 Left | 2 | PLA |

| Folding Limb 2 Right | 2 | PLA |

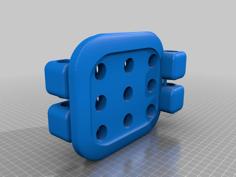

| Ball bearing holder | 6 | PLA |

| Lock mechanism 1 | 2 | PLA |

| Lock mechanism 2 | 2 | PLA |

Building Steps

Main Part

- Cut all components to the correct size

- Print all necessary 3D printed parts.

- Screw the main connector part to the big (bottom) and small (top) screen printing plate. Note: Use washers!!

- Then attach the metal sheet to the main connector.

- After this glue the rubber mat to the metal sheet.

- Nail the rubber mat to the endings of the screen printing plate to ensure a smoother way up the ramp and prevent sliding off.

Do this for both sides!

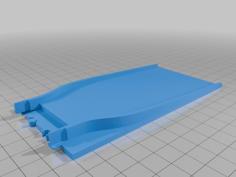

Folding System

- After the Main part was built. Put in the ball bearing into the folding Limb 2 Part and screw them with the M8 toghether.

- Glue the PVC Tubes into the folding limbs.

- Screw the folding limbs onto the main ramps with the ball bearing holders and the ball bearings. Note: Use washers!!

- After this screw the lock mechanism onto the ramp itself. Do this with the ball bearing holders and the ball bearings again. Note: Use washers!!

- Glue the short PVC Tubes into the handels and screw it onto the ramp.

After this the ramp now has the folding system attached and can be folded together.