https://jordi-stiller.myportfolio.com/sterne-und-milchstrasse

https://www.instagram.com/jordistiller/

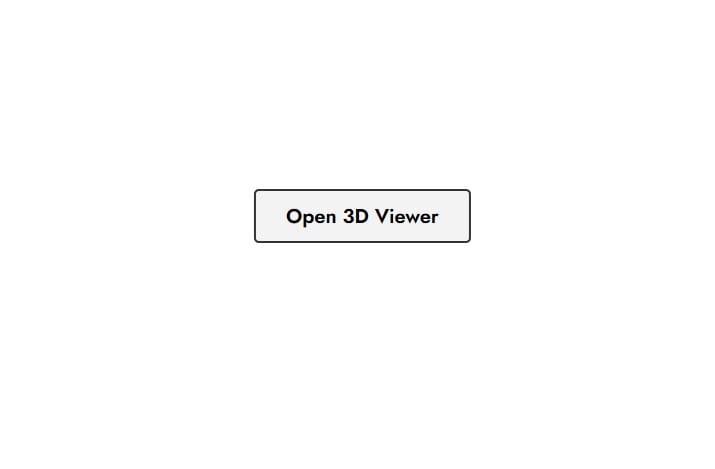

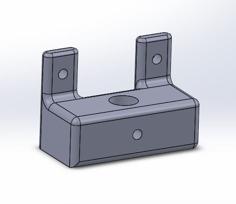

Two models are included: For 3D printing with plastic (more support arms) and a model for CNC milling with metal, for those who have a CNC milling machine.

To get more stability for a printed spider, I had to add twice the number of struts. From the point of view of diffraction physics, the 3 main struts seen in the spider on the right would be enough to achieve the main diffraction spike pattern.

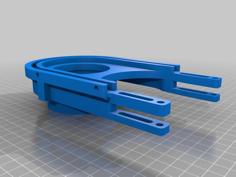

You MUST use metric melt-in threads if you have printed it. Cutting the threads into the plastic will sooner or later make the collimation of your Newtonian much more difficult due to temperature-related distortion and reduce the optical performance.

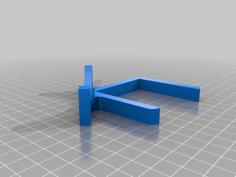

When melting the threads into the holes and installing the spider, be absolutely sure to orientate the spider correctly beforehand, the deeper hole in the center points away from the primary mirror, the focuser is parallel to the two shortened struts (position marked with a rectangle in the image). Before tightening the screws, make sure that the spider is aligned orthogonally (also called perpendicular or at a 90° angle) to the tube and the focuser.