Here is my report on 3D printing safely for animal enrichment: https://awionline.org/3d-printing-animal-welfare

OVERALL SUMMARY:

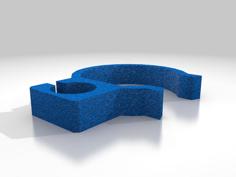

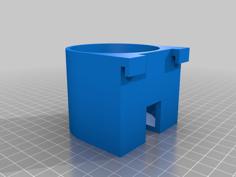

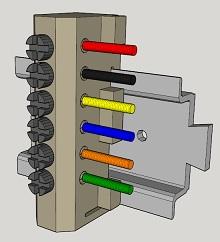

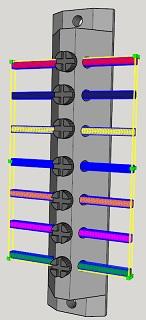

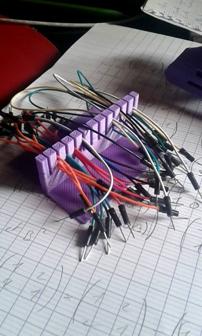

This is sized for 14 gauge welded wire mesh, and will mount on horizontal or vertical mesh because I'm awesome. Commonly, this mesh sized is used for building caging for birds, pocket pets, and rabbits. It will work for 1x1 inch mesh and 1x1/2 inch mesh. In theory, this would work for quarter-inch mouse-proof mesh but I don't have any on hand to test.

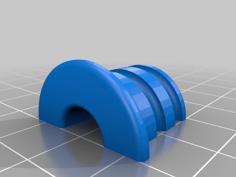

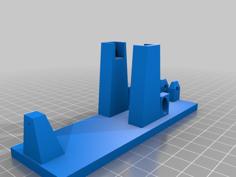

There are three types of mounts using this pop-on, pop-off system. (1) There is a double screw mount for branches, (2) a single screw mount for twigs, and (3) a pop-in mount for 3D printed objects. You can use MeshMixer or TinkerCad to mix the pop in mounting clips to any object you want and make it mountable to 14 GAW.

Wire mesh cages are often affixed in place in tight rows at commercial breeding or conservation facilities. When cages are fixed in place, it can be difficult to install or remove perching. Fixed row cages make it a terrible job to unbolt/unhook the cage, bring it down, then get two people. One person to hold up the perch and one to screw on the bolt or other hardware from the outside of the row cage, then reaffix the row cage.

This style of housing can be really good otherwise, where birds that are social species see and hear the presence of others and the space maximization allows for the biggest flight cages to fit on the site by eliminating human walkways around each cage.

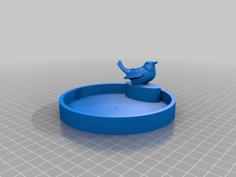

To allow for regular enrichment with natural branches (parrots love to chew wood, strip bark, chew on buds and leaves), as well as rotating durable plastic toys, I made this pop-on and pop-off branch mount for little birds.

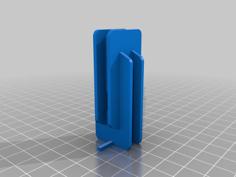

You will have to tinker with test prints sized up or down by 0.5-1% until it works perfectly on your prints. This is an exact fit print that will make a satisfying "click" and pop into place but then requires a bit of heavy upward pressure to pop off, reducing the chance that birds take down their own perching. If you have an exact fit to the wire when you print, it may make two clicks, one where the hooks pop into place, then one where the hooks grab onto the wire, so check that it is in solidly.

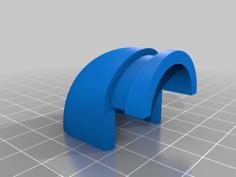

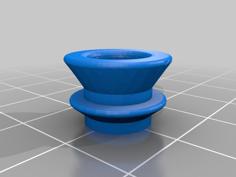

The weird hook shape provides a wide radius for bending to accommodate the wire, while still creating a tight fit that compresses solidly when bearing a load, instead of snapping.

The open bottom hooks allow for lots of support without adding so much friction that it is impossible to remove the perch holder.

SUPPLIES FOR NATURAL BRANCH:

no. 4 countersinking screws 3/4 inch long (I used Hillman product 35081)

3/16" wood drill bit

Power drill with pointy Phillips head driver bit for little screws

Branches, cut with a smooth base using a powered saw or sharp branch loppers

Optional: 2-party epoxy

Optional: heavy wire or unfolded paperclip

https://www.lowes.com/pd/Hillman-4-x-3-4-in-Brass-Flat-Interior-Exterior-Wood-Screws-75-Count/3036980

SUPPLY NOTE: You do not need any supplies if you are using the pop in an insert to attach a 3D printed plastic toy or perch instead of a branch.

NOTE: I had the misfortune of testing these in sub-freezing weather thanks to a major winter storm in Texas. What I learned was that the little hooks on the bottom failed almost exactly 50% of the time in extreme conditions. The screws and clips did not. So the little hooks need to be made BEEFY in the next iteration.

ASSEMBLY FOR NATURAL BRANCH:

Use the drill to insert the screws into the print, so that they stick out about 2mm or 1/16 inch out of the base. Press the plate against a flat cut branch, to leave two little marks from the screw. Pre-drill into the marks, 1/3-1/2 inch.

Optional: If you want the perch to last a super long time or be permanent, mix up a couple drops of 2-part epoxy. Dip a stout wire (16-14 GAW) or a paperclip into the mixed epoxy, then use the end of the metal wire to mush the drop into the pre-drilled holes. You just need a little epoxy in the hole, not smeared all over the branch. If you are using 2 or 5-minute epoxy, work quick! A 15-30 minute epoxy will give you more time.

Place the two screw points that just stick out past the base into the pre-drilled holes. Drive each screw all the way in. The base won't spin because there are two screw points, preventing rotation. Press a little with the drill, to keep enough pressure so the mounting plate will not lift up at all, staying perfectly flat to the cut branch. By pre-drilling, the screws should sink in like cutting into butter and not fight you. If you are using the single screw mount, you may want to wear a work glove and firmly hold the twig and mounting plate in place so the plate doesn't spin around as you drill.

Make sure the screws go in straight for the single and double screw mounting plates. The space between the screw heads accommodates a vertical cross-wire, so if you put them at angles you might not leave enough space for the cross wire to sink into the grove during mounting. If your vertical wire is on the outside and not the inside of the cage ignore this paragraph and drill at any angle you please. (Most people build wire mesh cages with the vertical wire on the inside so poop or fruit bits run down off the wire instead of getting stuck on the horizontal cross wire.)

When sinking the screws, you don't need to bury them in the mounting plate. The only goal is to hold the branch firmly to the plate so there is no need to crush the plastic to fully countersink the screws. Little screws are easy to strip so being on the gentle side will increase the chance you can re-use the perch mount later.

ASSEMBLY FOR 3D PRINTED OBJECT:

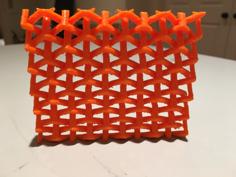

First, print the mounting plate and see if you need to size it up or down by a small % to fit. WRITE DOWN THAT PERCENTAGE! Then, print out the file "clip_in_insert_for_pop_on_mount_14_GAW_wire.stl" at the same % change. This is where it gets tricky. If it doesn't pop together fairly easily and create a firm, unmoving junction, then you will need to modify the % size of the clip insert. Each printer is different in layer size and accuracy so what works perfectly for me may suck for you. Finding the right % size for the clips may take three prints, one where you shrink or enlarge too much, then one where you cut the difference, then one where you tweak it to be perfect. Then write it down on a sticky note and leave it on your printer!

Once you have the rights % size change, you can Meshmixer or TinkerCad any model onto the clip_in_insert to create all kinds of new experiences for your animals, or useful things such as a cover for a feeding area to prevent gunk from falling into the bowl, or hang a swing from the ceiling - be creative and keep animal safety in mind!

The back of the pop-in mounting plate has a horizontal window in it. If the mount breaks down, or the toy wears out, you can use needle-nose pliers in the little rectangle window and pop the insert back out! Maximum re-usability!