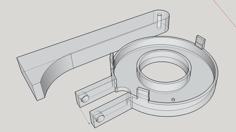

This is a DIY ceiling lamp made of a Philips Hue Lightstrip and 2m x 25mm x 25mm aluminium profile. I've build this lamp a few years ago and now I decided to give it an upgrade with diffusor, a suitable electronic box and small hooks for mounting purposes.

The diffusor works really well. I decided to design a diffusor which is able to emit light in an almost 90° angle to the side to give my shelf a better lighting, and it was successful. A nice side effect imho is that you can see the LED pattern from the side.

You will need:

•Philips Hue Lightstrip, 1 or 2m (or similar if wanted)

•90° aluminium profile 25mm x 25mm, 1 or 2m

•extension cable with a small (!) socket

•4 screws M3x6

•2 screw hooks

•2-3m thin cord

•2-3 cable tie sockets

•approx. 150g transparent filament (PLA or PETG)

•approx. 150-200g filament (PETG or ABS, wouldn't recommend PLA)

•the glue of your choice (hotglue will not work), like strong double-sided tape, superglue

(•reflective foil)

You will also need a 2,5mm drill bit and a M3 tapper

Step 1:

Printing the parts

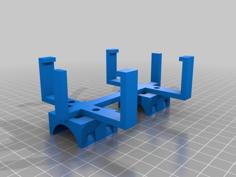

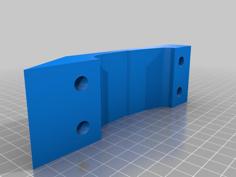

2x Hook

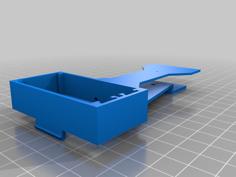

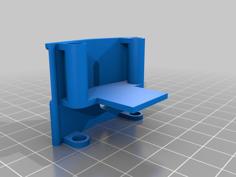

1x Electronic Box

1x Electronic Box Cover

1x Electronic Box Cover-Spacer (Accent Color) (USE SUPPORTS!)

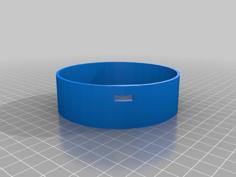

1x End Cap

1x End Cap Cable Housing (designed to fit the stiff Hue Controller cable, end cap especially for Hue controller electronics board coming up)

Diffusor (length and amount depends on your printer and your desired lamp length)

LED Strip Mount (same as Diffusor)

The Diffusor and the LED Strip Mount are 100mm long. You can scale them up (and of curse down) in the appropriate dimension to match your bed size. I've printed 8 pieces with 2500mm each for my 2m lamp.

The diffusors should be printed as hot as possible. That means you should also print slowly. My experiences are that printing cool and fast will make the print look more milky, while higher temperature and slower printing speed will make the print more transparent. You still get the diffusion effect without getting too much light absorbed by the diffusor.

The diffusion area is 0,8mm thick (z-direction), so 0,2mm layer height is optimal for the diffusors.

I HIGHLY RECOMMEND to use a "like new" print surface. You don't want scratches on the diffusors. Using a print surface with a pattern like PEI will make your diffusors look incredible good and can hide some flaws.

Step 2:

Take the hooks, place them symmetrical on the profile (my hooks are 1m apart), mark the 4 wholes, use a 2,5mm drill bit to drill the holes and tap them with the M3 tapper. After that use the 4 screws to install the hooks.

Step 3:

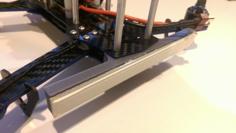

Tape down the Led Mounts

They are triangle shaped to match the inner rectangle of the profile. Use the glue of your choice to glue down all the mounts over the whole length. Hotglue won't work that well. It's cooling off immediately as the aluminium is absorbing the heat in a few seconds.

Step 4:

Dismantle the Philips Hue lightstrip (skip this, if you're not using Philips Hue or don't care about the max. brightness)

Carefully remove the silicone cover from the Philips Hue lightstrip. IMHO it reduces the brightness a bit. The downside is, you have to use your own glue, because the factory mounted glue is only on the silicone cover.

But in exchange you get a few percents more max brightness, the strip becomes 2mm thinner, which leads to more distance to the diffusor, which is what you want to get the best results in diffusion. Every millimetre more distance between strip and diffusor counts.

Step 5:

Use the glue of your choice to glue down the lightstrip on the mount you just glued in place (or use the preattached glue if you're using another strip or didn't dismantle the strip). If you have reflective foil, it's time to tape that also down on the inner side of the profile to improve the reflectiveness and make the light as soft as possible.

Step 6:

Slide on all the diffusors , With a bit of force you can also clip them on, but I would recommend to slide them on.

Step 7:

Put on the end caps.

Step 8 is pretty much straightforward as it's more or less installing a normal Lamp, but this time you have to place the socket from an extension cable and the power adapter from the lightstrip inside the self printed electronic box and connect them. The cover is screwed on, but make sure you put on the distance ring first and put the cable and cord through the hole. You will need the few extra millimetre from the ring for the Philips Hue power supply to close the box properly. I designed the distance ring to get a pretty accent with a contrast color without making the box more chunky.

One of the hooks is placed "inside" the box. The cable for the controller goes through the slot in the thread part.

Use the cable tie sockets on the profile as a cableway. You could also use a small cable tray, maybe a printed one. Right now my controller is glued on the profile, but I'm thinking of a way to place the electronics board from the controller in the end cap.

I guess the installation is pretty much self explaning.

BTW: I decided to use electric wire ferrules and my crimping tool for the cord instead of making knots. Works very well and looks better imho.

The end cap especially for the Philips Hue controller is currently in work.

Let me know if you have any suggestions.

UPDATE 09.08.2022

•changed length for diffusor and mount from 10mm to 100mm

•orientation changed for some models

•added end cap

UPDATE 12.08.2022

•added with diffusor / without diffusor comparison photo and electronics box wiring photo

•added provisionally end cap for the "with cable side" (designed to fit the stiff controller cable from the Hue controller)