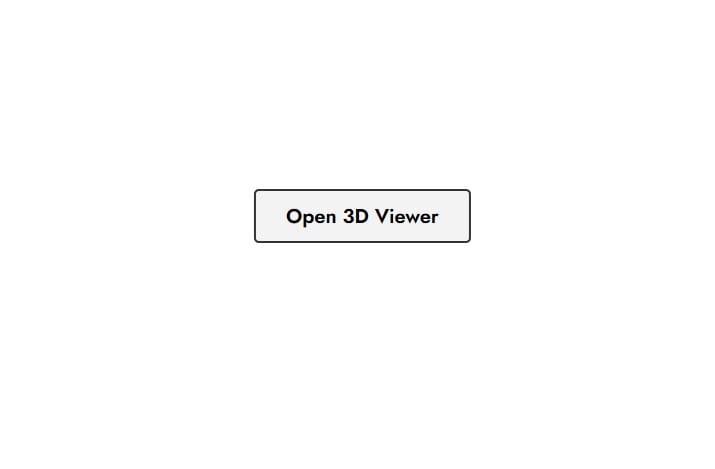

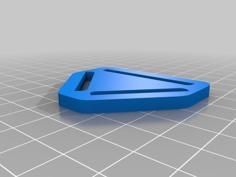

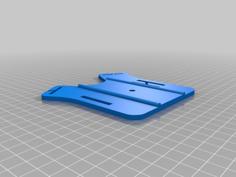

revised to v1.3- drip tray added to help prevent leakage. Bolting arrangement amended

revised to v1.2 radius corners to help with sticking to build bed, two end recesses added to allow for a screw driver to be used to prise the templates apart.

http://youtu.be/OaK46BK0zEY

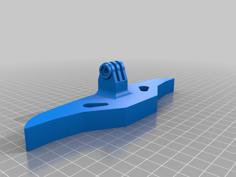

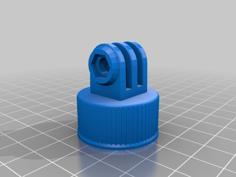

This is Based on the vibration dampening balls i already use , used on multicopters to isolate vibrations to the gopro camera range (will work with others).

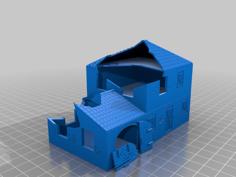

its a rough design, i will comeback and tidy up the design of this, once i get chance.i would like to have it hinged and a few other minor tweaks to make pouring the silicone in to the mould easier

this is a version v1.3 the photos are the results of my v1 attempt, which came out well for a first attempt at moulding, but i modified the files a little, based on my first experiences.

bolt the two parts together with m3 bolts, don`t over tighten.

mix up your silicone and catalyst and pour.

i used 50g of rtv 2020 silcone/catalyst as a guide of quantity

checkout how to make the rtv silicone mix on google etc, there is plenty of info on there, you can see from my attempt, that i had too much air get in, this was totally my fault due to it being my first time using this silicone mixing. i know my next attempt will be far better, now i know what i am doing.

i used medium hardness silicone as a guess, i have not tested it in anger yet but i will get round to it shortly.