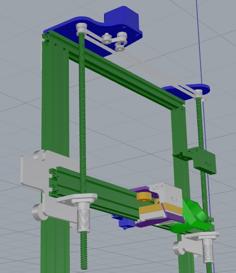

It's a prototype which works for many Replicator 1 clones like the CTC Bizer, Wanhao Duplicator 4, or Flashforge Creator (copies of the Makerbot Replicator). Please let me know if something is wrong, so I can improve it.

- NEWS

- 16th January 2019 : Finally, after several years of titling "working on an even better version for flex" I am confident to present you an even better version. It was tested up to 60mm/s, 0.16mm layer height with SainSmart TPU (medium soft TPU, Shore 95A) successfully. You will find the new version under the name "2019_improved_filamentguide_flex" containing all parts needed. Attention, the backplate is 0.7mm thinner now for better filament guidance. To use the flattened backplate you have to use a screw with a very low profile screw head, or the arm will crash into it! You got 1.3mm space. The best solution for me was to grind down the existing screw's head.

- 4th June 2016 : new bottom part added, which is better suitable for flexible filaments. I am working on an even better version, where are no bigger gaps at all. Running tests with TPU @50mm/s and 0.2 layer height at the moment.

Hi folks!

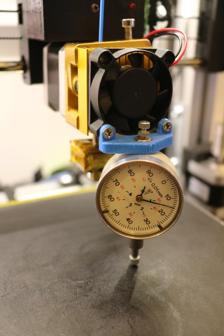

I really liked the idea KimBrown had about mounting an existing aluminium/aluminum feeder arm to the CTC without the need to print one in plastic. We all know that plastic is aging or can break, due to heat or mechanical influences. So I intended to install two of the cheap aluminium arms for the (RepRap) i3 out there, which can be ordered via ebay, amazon and others (search for "mk8 aluminium extruder"). They are strong, spring loaded and there's a thread to screw in a PTFE-Tube coupler (see the images).

I had some issues using the original version. There was two main aspects.

1) The filament was not guided directly to the stepper-gear and roller-bearing, so it got stock sidewards or on the tooths of the stepper-gear when pushed into feeder by hand.

2) The filament was not guided directly to the hotend and kept crashing on the edge of the metal tube at the aluminium block sometimes.

SOLUTION: guide filament's way down to the hotend.

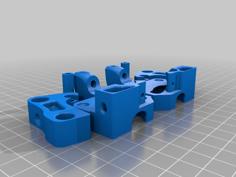

- added top part which guides filament between gear and roller-bearing

- modified bottom part which guides filament to hotend

- changed some diameters to make a nicer fit

NOTE:

- Updated 2019 version: It was tested up to 60mm/s, 0.16mm layer height with SainSmart TPU (medium soft TPU, Shore 95A) successfully. You will find the new version under the name "2019_improved_filamentguide_flex" containing all parts needed for a right-hand sided extruder. For left-hand sided (or dual of course) you have to mirror the parts yourself, which is easily done in every slicer available on the market.

If the newest (tightest) version does not fit your printer you should stay with the older version for flex. The older is suitable for 40mm/s at 0.16mm layerheight with Shore hardness 95A TPU. - Don't forget to change the "start.gcode" to reduce the flowrate for the cleaning script, it's very important for flex filaments (take a look into the comments). Also decrease the retraction speed to around 5 or 10 mm/s.

- Mounted without drilling additional holes. Mounted via original mounting points available at the parts.

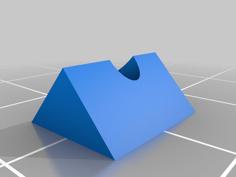

- There are two versions of the bottom part, one which is meant for metal tubes which are low above the alu block ("bottom_part_low.STL") and one for high tubes ("bottom_part_high"). Both are a bit different.

- IMPORTANT: there is more than just one version of these arms for the i3. If you want to add some fancy PTFE tubing, you need to buy the one which has a M6-thread for a coupler for PTFE/Teflon tubing (like the one installed in my images). Most of the RepRap i3 ones don't have one. I accidently ordered two different and one had no thread and a bit other positions for the holes, so I had to modify the arm in my workshop and added the missing thread. If the top part does not fit to the version you ordered, tell me and I will try to adjust the holes to make it fit for your needs. Otherwise try to make the existing holes larger in your printed top parts with a drill.

- the top part needs some kind of flat washer between printed mounting points and roller-bearing to make the roller-bearing rotate nice and freely. I never tested it without the washer, so it could work, maybe give it a try if you have no other choice.

I used one made of Teflon/PTFE which is 0.4mm thick, which is nearly perfect. If you have no such small washer you can try to print the one included in this thing's files.

That's all. Work's nice and flawless for me. Filament can be pushed directly by hand into the hotend with tiny force.

Have fun!