Heyho :)

Greater Update 27.12.202: V2

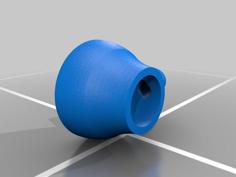

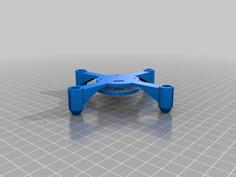

I redesigned the Glasses & Inlets for a sturdier fit and an easier assembly!

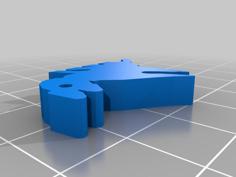

Inlets are symmetrical now.

Inlets lock in place a lot sturdier and have some tolerances.

Templess taper down at the end for an even better comfort fit.

Center brdige is a little more massive for a higher stability.

Addon 28.12.2023 Hinged temples: 2 Versions: Print in Place & Pin in Place .)

https://www.thingiverse.com/thing:6404646

I had some glasses printed for a party this year. I didn't like the poor fit, rattiness or the fact that most of the models kept falling off or breaking quickly.

That's why I sat down and designed my own. This one is designed for FDM printing and doesn't need any extra parts or reworking.

The only "disadvantage" is that you can't close it. However, closed glasses don't look good at parties anyway :D So it's better to pass them on and share them if you don't want to wear them anymore!

Customization:

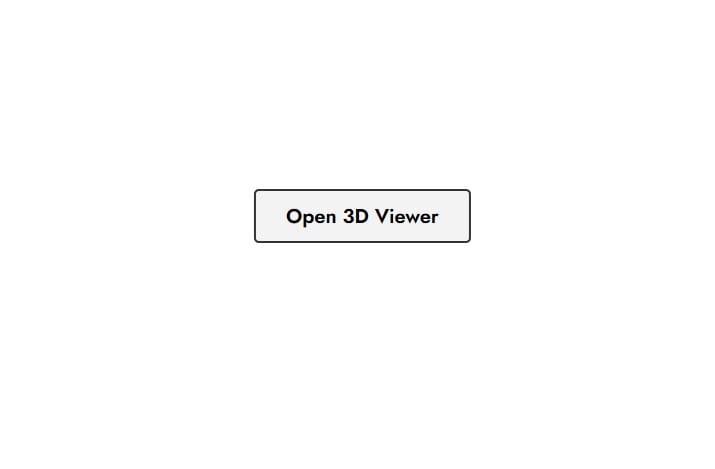

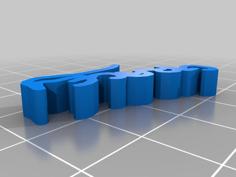

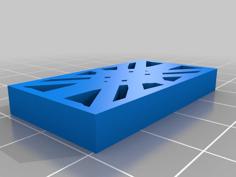

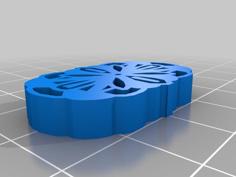

You can print the lenses with the infill of your choice! I recommend not choosing a pattern that is too dense so that you can still see well :D 15 - 20% is usually enough!

To see the infill only set the Top and Bottom Layers to 0!

Scalability:

You can also scale the glasses to make them fit even better! For my daughter, for example, I reduced the width of the glasses in the slicer by 18 mm so that they fit better! (Scale all 3 axis at the same factor!)

Printing tipps:

I used PLA, 3 Perimeter, 25% infill with the temples and 100% Infill with the main body. Glow in the Dark will look cool too! If you have problems with breaking parts you can also use tougher materials like PETG.

Assembly:

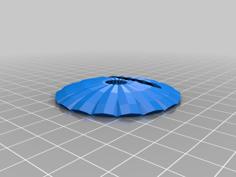

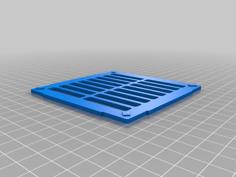

All parts are designed for a stable press fit. The temples have to be pressed into the glasses with quite a lot of force and then hold very well! If it doesn't work at all, you can also scale the temples a little smaller and reprint them.

The assembly of the brackets in the main frame requires some force. Especially with stiffer materials such as PLA. To simplify this process, you can apply some candle wax to the locking mechanism to make insertion easier. The brackets still lock very firmly.

Post processing:

Not really necessary. But if you really want to go all out, it's certainly worth joining all the parts together with a little superglue.

For a possibly even better seat shape, you can also heat the parts slightly and glue them together.

Have fun and a happy new year! :)