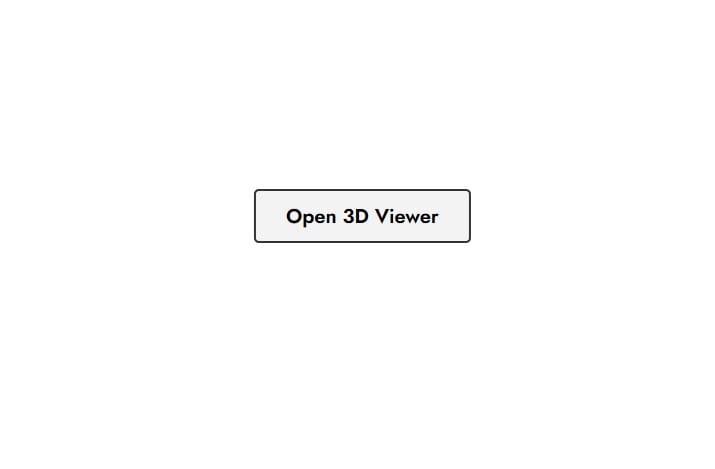

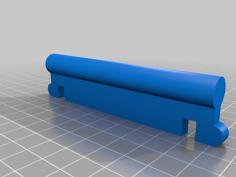

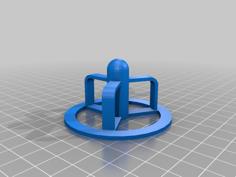

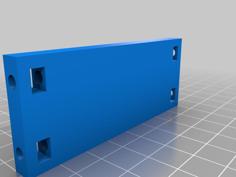

This is a ball bearing supported filament spool holder that is compact, can mount using the Wanhao i3 frame spool bolt holes, and has a built-in filament guide. The filament guide is a captive ball joint that will fit 4mm diameter teflon tubing. I haven't yet developed a good solution for capturing the bottom end of the filament guide tube at the extruder, so for now I'm using a short length of teflon tube held only at the guide end in order to keep control of the filament as it leaves the spool.

My priorities for this cradle design were compactness, ball bearings for very low friction and force required to pull filament off the spool, and to keep control of the filament and provide just enough friction in the filament guide to keep the filament spools from turning too much on the ball bearings as filament unwinds.

The filament cradle is printed out as a single piece.

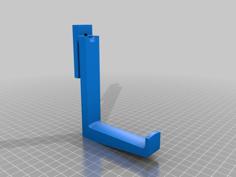

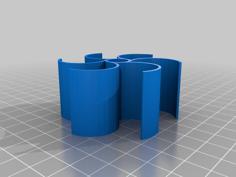

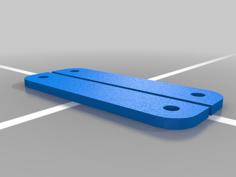

The spindle is designed to accept two end caps (I refer to them as bobbins) with appropriate spacers to ensure that the end caps are centered on the spindle. I designed this originally for my Monoprice 1kg spools, and the end caps fit the Monoprice spool bore. With the Monoprice inner spacers, the Monoprice end caps, and the spindle, the end caps touch the inner ring of the skateboard-style (VXB 608 ZZ) ball bearings to keep the spool centered and trapped on the spindle.

I've designed inner and outer spacers, and an end cap, that will allow Hatchbox 1kg spools to be mounted on this. I'm currently printing these out to test them, and will add them to this project as soon as I know the dimensions are correct.

I invite others to work out parameterized versions of the end cap, the spacers, etc. to allow people to easily fit other brand spools on this cradle. To make this easier I've attached my SolidWorks source files for these parts. I'm brand new to SolidWorks, and this is my first SolidWorks project, so I acknowledge that the way I did these is probably not optimal.

Also, if someone has any good ideas to make a better spindle/end cap combo design to make this more extensible, more simple, or whatever, please feel free to do it and link it back to this cradle project. I'm brand new to designing things, so I know there's got to be much cleverer ways to do this, and I'd love to see it happen.

EDIT 13 November 2016: I just added STL files for inner spacers and end caps that fit the eSun 1kg spool and the Hatchbox 1kg spool. This cradle now contains everything necessary to support Monoprice, eSun, and Hatchbox 1kg spools. As I pick up new brands with different spool widths and bores I'll make end caps and inner spacers to mount them on my cradle, and I'll add them to the project. These are easy to design, though, for any arbitrary spool that will at least fit within this framework, which should be most spools.