Hey all

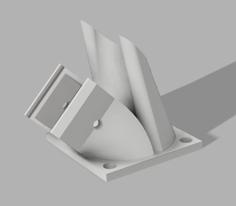

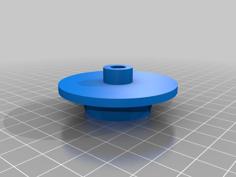

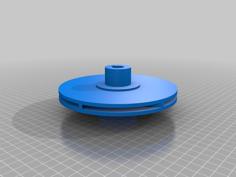

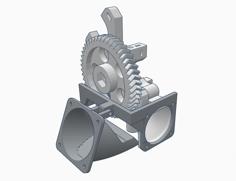

I designed a 200mm backwards curved impeller because I couldn't find one on here anywhere!

VIDEO OF MY PROTOTYPE PRINT RUNNING

https://www.youtube.com/watch?v=KhTisIjnOTw&feature=youtu.be

This design is similar to EBM Papst motorized impeller, however, this one <$5 to print, vs $200+ for that one!

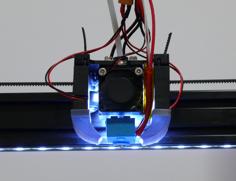

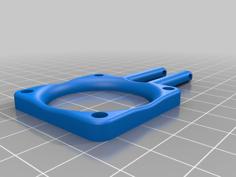

This type of fan is also known as Plug Fan. Only an inlet ring is required; NO scroll case is required to get good airflow. The chamber the fan is inside will be pressurized, and it will intake from the middle. You don't need a proper inlet ring for this one, just use a flat sheet of something with a hole under 4cm away from the front of the fan's top ring. I tested it inside a cardboard box. Direction of rotation is CCW facing the front inlet. This is to allow it to be powered with DC brushless fan motor (you will burn it out if load is too high though)

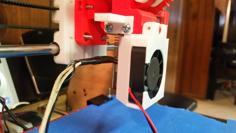

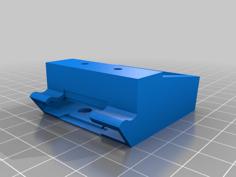

I am using a printer's carriage DC motor to drive it. Using around 15V DC, it rotates at a pretty slow speed, but moves a TON of air for the noise it produces. Increasing the DC voltage to 28V allows it to rotate much faster, and suck a large volume of air through quietly. However, this may burn out the motor if run like this for a long time.

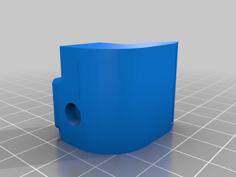

I provided the mount to let you attach it to the motor shaft. You have to drill the hole yourself. If you want to have a different middle part design please let me know and I will upload the autocad file for you to edit? I used some small screws to screw it in.

BALANCING IS VERY IMPORTANT; if someone comes up with a good way, please do share. I did it with trial and error with tape and made it permanent by measuring the same weight of epoxy resin.

Glue the inlet ring firmly to the bottom using epoxy. If you don't, the vanes will shake and make noise.

Please be careful with this fan. Even though it does not require a casing, installation within an enclosed situation is highly encouraged for safety reasons. The rotational inertia and sharp blade edges are dangerous when it is running, and it is advised to not run the fan too fast and inspect rotor for damage before starting . I am not responsible for any issue caused by your application of this file.